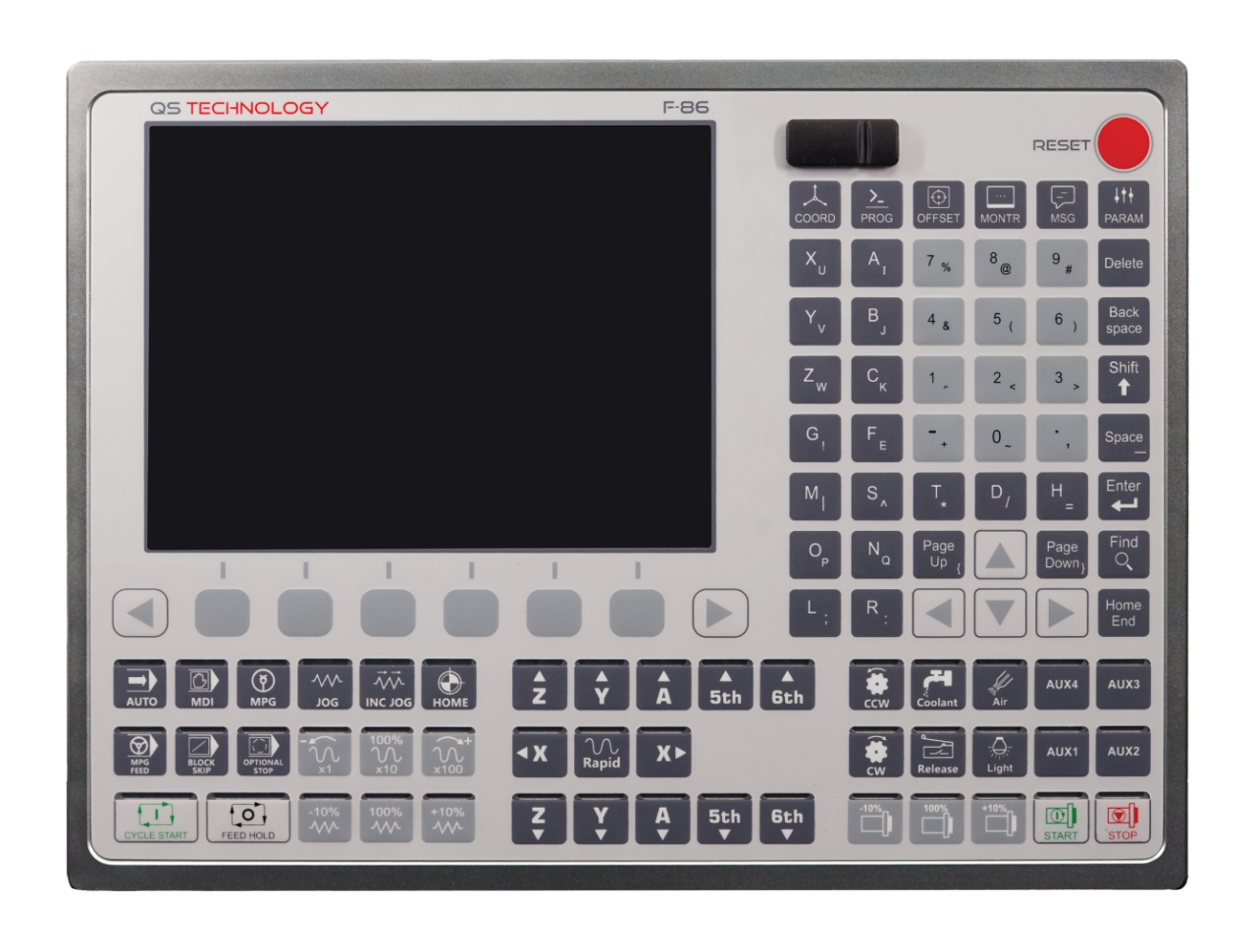

The CNC controller F86 is a new product from QS Technology, featuring a larger design with an 8-inch display that has a resolution of 800 x 600 pixels. This makes operating and monitoring machine information more intuitive and easier for the operator. Additionally, the modern and fresh interface design is a significant advantage that attracts users at first glance. The F86 controller allows for the simultaneous control of 4 to 6 axes and includes an Encoder phase Z feedback function, enabling operators to return axes to the home position more accurately. With its high-performance processor, the F86 controller integrates a PLC processing module, allowing users to monitor operational status and program extended machine functionalities. Moreover, the ability to program Macros is a strong feature of the F86 controller.

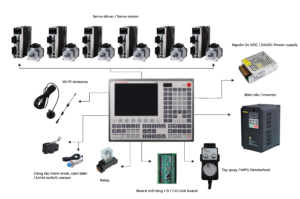

Back side of F86 Controller

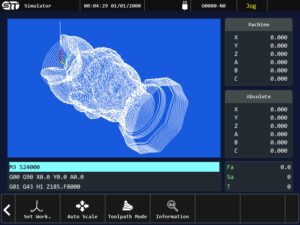

The interface provides a detailed visual simulation of the machining program profile, which can be displayed in 2D milling, 3D milling, and 2D and 3D engraving modes.

Some application photos of the product on machines have been taken by customers

| Description | Values | |

|---|---|---|

| Product specification | Dimension | 320 x 185 x 30 (mm) |

| Outer case materials | Aluminum anodizing | |

| Max. PLC Axis | 6 | |

| Standard Axis | 6 | |

| Max. Axis (Optional) | 6 | |

| Max. Spindle | 2 | |

| Max Spindle Simultaneous Axis Control | 6 | |

| Min. Control Unit | 0.0001 | |

| Max. Number Of Program Coordinate | 18 | |

| Max. Number of Table Tools | 40 | |

| Look-Ahead | 250 | |

| Block Processing Time | 250 | |

| Hardware | Standard I/O | 24/16 |

| Optional I/O | 256/256 | |

| DA | 1 | |

| Monitor | 8 Inch | |

| RS485 | 1 | |

| USB port | 1 | |

| Compensation features | Backlash compensation | Yes |

| Pitch Error compensation | No | |

| Basic features | MPG Simulation | Yes |

| Dry Run | Yes | |

| Optional Stop | Yes | |

| Single Block | Yes | |

| External Offsets | Yes | |

| MPG Offsets | Yes | |

| G-code support | G00 – Positioning | Yes |

| G01 – Linear Interpolation | Yes | |

| G02 – Circular/ Helical Interpolation – CW | Yes | |

| G03 – Circular/ Helical Interpolation – CCW | Yes | |

| G04 – Dwell | Yes | |

| G17 – X-Y plane selection | Yes | |

| G18 – Z-X plane selection | Yes | |

| G19 – Y-Z plane selection | Yes | |

| G20 – Inch perform | Yes | |

| G21 – mm perform | Yes | |

| G28 – Return to reference position | Yes | |

| G30 – 2nd, 3rd, 4th reference position return | Yes | |

| G31 – Skip Function | Yes | |

| G43 – Tool length compensation in positive direction | Yes | |

| G44 – Tool length compensation in negative direction | Yes | |

| G49 – Tool length compensation cancel | Yes | |

| G53 – Machine coordinate system setting | Yes | |

| G54 – Workpiece coordinate system selection 1 | Yes | |

| G55 – Workpiece coordinate system selection 2 | Yes | |

| G56 – Workpiece coordinate system selection 3 | Yes | |

| G57 – Workpiece coordinate system selection 4 | Yes | |

| G58 – Workpiece coordinate system selection 5 | Yes | |

| G59 – Workpiece coordinate system selection 6 | Yes | |

| G61 – Exact Stop Mode | Yes | |

| G64 – Cutting mode | Yes | |

| G65 – Macro call | Yes | |

| G73 – High speed peck drilling cycle | Yes | |

| G76 – Fine boring cycle | Yes | |

| G80 – Canned cycle cancel | Yes | |

| G81 – Drilling cycle | Yes | |

| G82 – Drilling cycle of dwell on the hole bottom | Yes | |

| G83 – Peck drilling cycle | Yes | |

| G84 – CW tapping cycle | Yes | |

| G85 – Boring cycle | Yes | |

| G86 – High speed drilling cycle | Yes | |

| G87 – Fine boring cycle of back side | Yes | |

| G88 – Semi-automation fine boring cycle | Yes | |

| G89 – Boring cycle stops and the end of bottom hole | Yes | |

| G90 – Absolute coordinate systems | Yes | |

| G91 – Increment command | Yes | |

| G92 – Work coordinate setting system | Yes | |

| G93 – Feed in mm per minute | Yes | |

| G94 – Distance/F (min | Yes | |

| G98 – Return to initial point in canned cycle | Yes | |

| G99 – Return to R point in canned cycle | Yes |

Recognized as the leading entity in Vietnam, developing, applying, and trading CNC control products. After several years of product development, our products have been widely applied in the industry, and we have gained trust and attention from both domestic and international customers.